Innovation

The Best Partner for Our Customers

"Innovation" is one of the driving forces for Nanya's growth and competitiveness and one of our four core values. We shall strengthen product research, development, and manufacturing to satisfy customers' diverse demands and become the best memory partner for the smart generation.

Statistics

-

8.8 %

R&D expenses accounted for 8.8% of revenue and R&D personnel accounted for 26.8% of employees. These demonstrate Nanya's focus on technological development

-

100 %

Complete product life cycle inventory on 100 percent of products

-

207 cases

Rewards for improvement proposals reached 207 cases, showing that employees adapted well to the culture of work improvement

Strategy and Performance

Innovation Committee

In order to implement innovation management, create a culture of innovation, and enhance the company's innovative energy and value, Nanya especially set up the Innovation Committee, a cross-departmental unit, formed by the senior management and chaired by Executive Vice President (EVP). The Innovation Committee is positioned to coordinate and plan the overall innovation strategy, setting short, medium and long-term goals.

Investment and Output in Innovative R&D

Incentives for Innovation and Results of innovative activities

"Innovation" is one of the driving forces behind Nanya's technological growth and competitiveness enhancement and one of our core values. To encourage employees to propose innovative ideas, the Company holds annual innovation competitions, offers patent rewards and rewards for improvement proposals, and organizes essay competitions and the best team competitions. We recognize and reward innovative ideas proposed by each employee, hoping that all employees will internalize the spirit of innovation.

-

Incentive innovation mechanism

-

Results of innovative activities

In addition, we attach great importance to technology R&D. We incorporate external innovation into our R&D in open and innovative ways, and accelerate and expand technology R&D. We have worked on basic research, product design, and product testing for next generation memory with National Taiwan University, National Central University, Chang Gung University, Industrial Technology Research Institute, and testing equipment suppliers. We have also partnered with manufacturers of masks and machinery in joint development of 10 nm process and materials. Through customized Wafer Level Packaging and multiple application products developed rapidly with downstream system developers, Nanya has launched new open innovation programs every year in the past four years in coordination with the Company's short, medium, and long-term R&D plans.

Technology R&D open innovation program

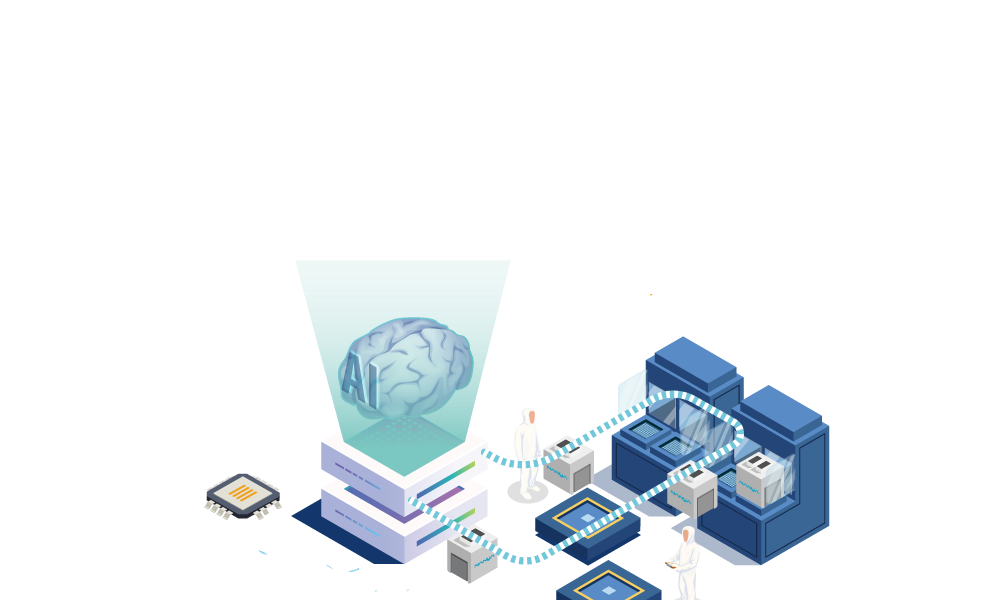

Nanya Smart Factory

Nanya's 12-inch wafer fab has all the necessary infrastructure that a smart factory requires, including highly automated production lines, Fab IoT, large numbers of sensors, and big data integration. The fab utilizes AI technology in eight important applications, including machinery diagnosis, process control, productivity improvement, quality inspection, yield analysis, process development, work safety, and information security management.

Currently, Nanya has developed a number of innovative production line applications, including the machinery diagnosis, advanced process control, optimization of production schedules, projections of work in process, smart handling, wafer probe testing, defect image recognition, and pattern recognition of wafer yield. As of the end of 2021, Nanya completed the development of 70 AI applications that can improve product yield and quality, reduce the number of products discarded due to defects, increase the utilization of machinery, reduce equipment maintenance expenses and raw material consumption, and increase production capacity and more effectively utilize human resources. Annual benefits reach NT$330 million. As we continue to develop new AI applications, we expect annual benefits to increase by 10% each year, and the total amount of benefits in the next 5 years to reach NT$2 billion.

Green Product Development

Nanya and clients both aim to protect a green planet. We implemented the Life Cycle Thinking (LCT) and the Design for Environment. For a long time, we have made an effort to research and develop advanced and highly efficient eco-friendly products. We not only have helped clients develop products with low energy consumption design, but also have engaged in hazardous management and conflict minerals management through our influence on supply chains.

Product Life Cycle Assessment

We used the Simapro, a life cycle assessment tool, to conduct life cycle assessment on 100 percent of our products, calculated environmental footprints of products, and identified directions for future improvements. In the meantime, the company would use the product environmental data and coefficients accumulated through analysis processes to build a decision support system for green product development. The company gave multiple considerations on the requirements, and conducted quantitative life cycle assessment on products in each life cycle stage.

Three main hotspots of greenhouse effect listed in the results of the 2020 product LCA results

Green Product Design

Nanya started researching and developing new generation process technology of 1A-nm and 1B-nm in 2017, and planned to develop products with high integration, faster speed, and lower energy consumption, such as DDR4/DDR5. Driven by the demand for 5G communications, cloud, AI, and smartphone memory upgrade, DDR5 and LPDDR5X (low power double data rate memory) became the main supply of new generation memory. Compared with current mainstream memory, new generation memory possesses faster transmission efficiency while saving energy due to lower operating voltages. When comparing DDR4 with DDR5, average power is about 16% lower, but bandwidth is doubled.

DDR5&LPDDR5X provided specifications that save more electricity with high bandwidth/high speed

Nanya has focused on the development of advanced processes, and began independently developing 1A process technology in 2017; trial production began in 2020. 1A process technology will significantly shrink the size of chips and increase the capacity of a single wafer by 30%. Furthermore, we also began developing 1B process technology in 2019 and expect to begin trial production in 2022. 1B process technology further shrunk chips made using 1A technology and increased the capacity of a single wafer by 30%. This will allow factories to further achieve energy conservation and carbon reduction goals while achieving the same production capacity.

Nanya DRAM Technology Strategy

R&D Policy for Low Energy Consumption Products

-

Nanya continues to develop advanced manufacturing processes, so the energy consumption of new generation products developed with new processes is reduced by 15% compared with the previous generation.

-

Nanya cooperates with major chip customers, adopting the method of multi chip package (MCP) to reduce back-end assembly and testing as well as energy consumption.

-

Nanya strengthens the development of low energy consumption product lines and enlarges product portfolios in order to satisfy the need of various mobile devices and electronic products.

-

Environmental external benefits

Nanya actively researches and develops low energy consumption products, and assist clients lower demand for energy during their usage of electronic products so that greenhouse gas emissions can be reduced.

-

712 GWh of electricity saved

- Product: low power DRAM and 20nm consumer DRAM

- Scope: Total sales volume in 2021

- Calculation: Based on the quantity of products sold in one year, and compared the energy consumption of the aforementioned DRAM products with that of the previous generation

712 GWh of electricity saved = Annual electricity consumption of 189.710 households = 357,509 ton-CO2e reduction = 919 times the carbon absorption of Daan Forest Park in an entire year

Hazardous Substance Free Product Management

In 2005, Nanya established the Green Product Promotion Committee (GPPC) to promote hazardous substance free (HSF) management. During the product manufacturing process, we continued to prevent pollution, save energy, reduce wastes, and avoid hazardous substances. Through concatenating suppliers of raw materials, process materials, rear-section packaging outsourcing and packaging materials, Nanya built an effective green product supply chain with upstream and downstream suppliers in the supply chain so as to conform to the laws and regulations of current global environmental protection trend. all of our products needed to conform to international regulations, such as RoHS, REACH, Packaging Instructions, and WEEE, as well as clients' requirements, moreover, we do not use chemicals concerned by the IEC 62474. In addition, through the establishment of HSF management system of materials, we ensured that the wafers produced, rear-end IC packaging, and DIMM module products would conform to the international regulations and related specifications of clients towards HSF management.