Innovation The Best DRAM Partner for the Smart World

Innovation, as one of the four core values of Nanya, is the foremost drive of our growth. We continuously enhance our competitiveness in R&D to satisfy a broad range of demands, striving to provide the optimal solutions for our customers.

-

R&D expenses: 25.3% of total revenue

R&D personnel: 28.9% of total employees 25.3 % - Benefits generated by 110 AI applications in 2023 380 million

- Patents granted in 2024 953 cases

Innovation: Strategies and Highlights

R&D and Innovation

R&D and Innovation

Smart devices empower a more productive life with less energy consumption, in which DRAM plays a critical role. Nanya invests consistently in R&D to address the ever-growing demand and provide value-added services. We strive to develop next-gen products, 10nm-class process and 3D stacking technologies secured by IP and trade secret protection.

- Leading product 16Gb DDR5

- Clarivate Top 100 Global Innovator 2023

- Granted patents as of 2023 > 6,800 cases

Culture of Innovation

To foster a culture of innovation, every year we organise internal competitions on research & innovative proposals, and provide incentives for patent and proposal optimisation. By supporting these activities, we aim to encourage experimentation and unorthodox thinking.

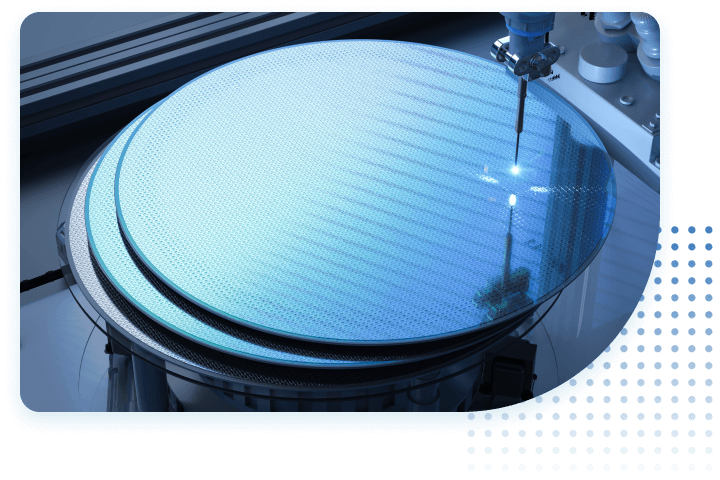

Nanya Smart Factory

Nanya Smart Factory

Nanya's 12-inch wafer fab is equipped with complete infrastructure for smart factory, including automated production lines, IIoT, and big data analytics. We further enhance yield, quality and output with AI applications, including predictive maintenance, production planning optimisation, quality inspection, yield analysis.

-

Developed AI applications

as of 2023 110 -

Expected benefits

in the next 5 years NT$ 2 billion -

AI engineers

cultivated 450

Green Product Development

Green Product Development

We develop products with Life Cycle Thinking and the Design for Environment approach. We help our customers to build energy-efficient solutions, required the supply chain for hazardous substances and conflict minerals management. Supervised by Nanya's Green Product Promotion Committee (GPPC), our product development takes into account the environmental impacts from procurement, manufacturing, transportation, product use, disposal, and recycling.

-

Green Product Design

Nanya started independent from 2017 with our 1st generation (1A) of 10nm-class technology. 1A technology could increase output per wafer by 30% and has entered small volume production in 2022. The development of the 2nd generation (1B) technology began in 2019, which will enter mass production in 2024 to increase output by another 30%. The elevated productivity also means lower energy needed for the manufacturing process.

-

Output increase by generation

Sustainability powered by greener products

- Output per wafer increase 30 %

- Energy consumption reduced 15 %

- Energy saved at customers' end > 51,415 million kWh

DDR5 & LPDDR5X delivers higher bandwidth & speed with better energy efficiency

ESG News

ESG News

Facebook

Facebook